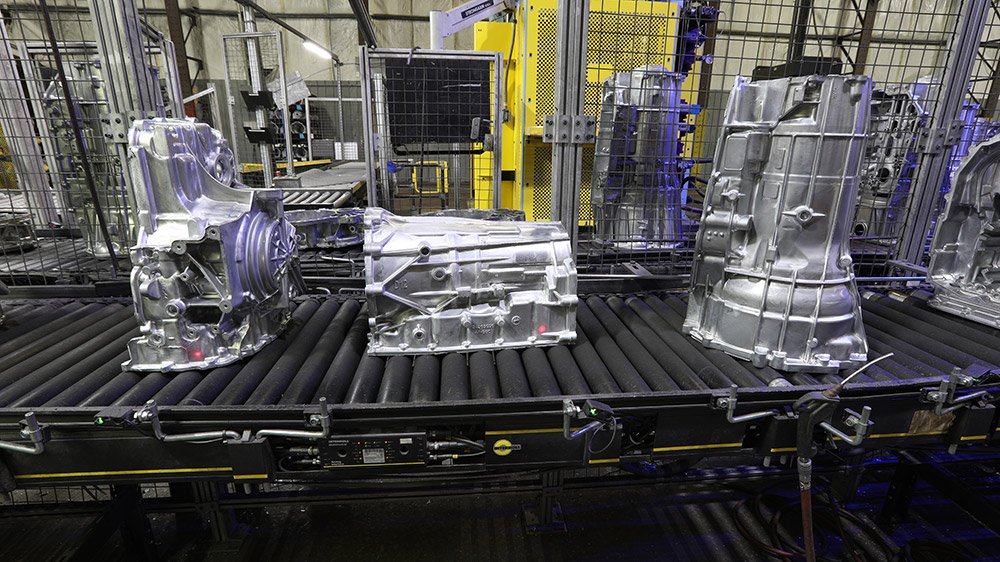

Conveyor Systems

TURNKEY CUSTOMIZED SOLUTIONS

Stac provides customized turnkey conveyor solutions and belt conveyor options for all your industrial conveying needs. From initial assessment of customer requirements and goals, our engineers build design proposals for your consideration. Once a solution is determined, we will execute the project plan, including all materials, installation of project, and in-depth training on system operations and controls.

SYSTEM DESIGN + LAYOUT

We start with an assessment of your needs and execute a fact-finding mission to develop a conveyor type perfect for your application. Cost and time savings are top priorities for your solution.

TURNKEY INSTALLATION

Our installation team is dedicated to installing your equipment safely, properly and efficiently the first time. Our diligent focus on protects production time.

CONTROLS

Control systems are designed to meet the needs of the project as cost effectively as possible. Our engineers will integrate into existing control systems and almost any automation platform.

SAFETY

We address all potential safety concerns through the use of safety technology such as interlocks, e-stops, light curtains, vision systems and physical barriers.

TRAINING

We feel customer satisfaction should be the end result after the project is complete. Dedicated site time with Stac Control Engineers ensures you receive the training and guidance you need to answer any questions you may have on your new conveyor system.

CONVEYOR TECHNOLOGIES

These conveyor systems help transport and distribute products throughout a variety of facilities such as Distribution Centers, Manufacturing Facilities, Beverage Distributors, Industrial Warehouses, Assembly Operations and more.

SEE IT IN ACTION

These products save time, effort and money by moving your products throughout the creation process. See how our automated conveyor system can revolutionize the way you work.

Semi Automated Palletizer

Diverter System

Zero Pressure Accumulation Conveyor

Motor Driven Roller Zero Pressure Accumulation

Line Side Part Delivery

Packaging Conveyance and Automation

Modular Conveyor Platform

Interroll Crossbelt Sorter

Interroll Modular Conveyor Platform